No products in the cart.

The E5 requires no compressed air; therefore, you have maximum freedom in the choice of the installation site, and you also benefit from minimal operating costs. The open system architecture of the E5 makes your entry into the digital production of dental restorations quick and easy, and it fits perfectly into your workflows.

Optimize your digital workflow, enjoy maximum freedom and achieve perfect results with optimum efficiency.

5-axis dry milling at the highest level. With extremely simple operation.

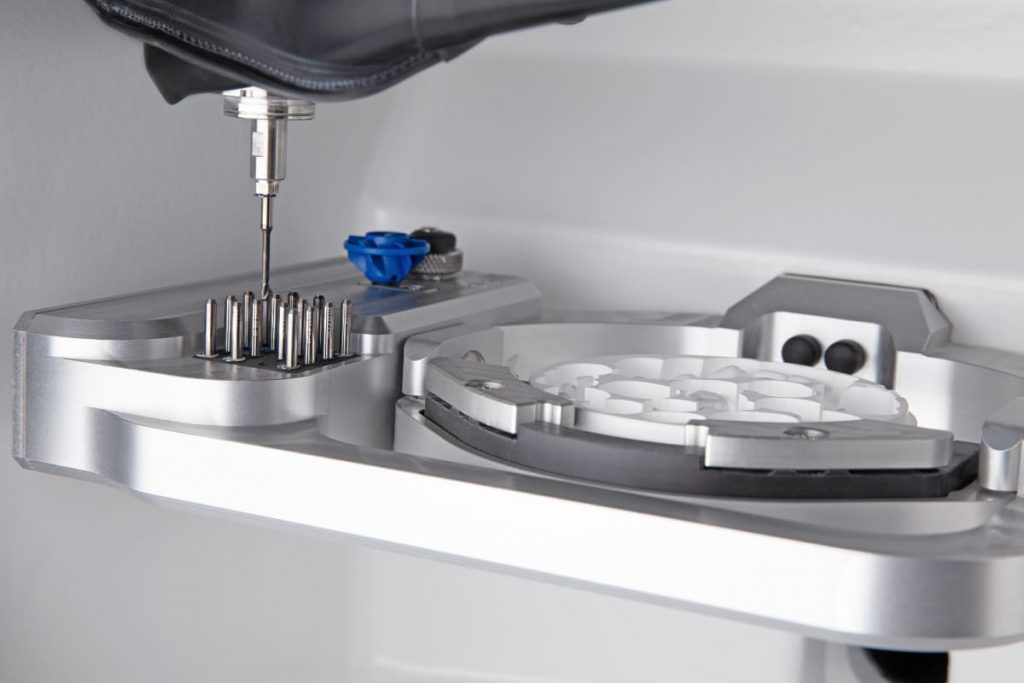

The E5 not only allows you to mill discs; you can also use the appropriate holder to process up to 6 blocks of different sizes with minimal effort.

The automatic tool changer can accommodate 16 standard tools and an AIRTOOL.

LET THE WORK FLOW.

Despite its compact design, the E5 offers a generous working chamber with plenty of space in which to clamp the workpieces and load the automatic tool changer.

BEST RESULTS. WITH EASE.

The E5 was developed with an optimized weight of only 43 kg and is manufactured with only the highest quality industrial components, thereby fulfilling our claim of Creating Perfection. How do you benefit? The E5 achieves impressive, first-class results.

The E5 requires no compressed air; therefore, you have maximum freedom in the choice of the installation site, and you also benefit from minimal operating costs. The open system architecture of the E5 makes your entry into the digital production of dental restorations quick and easy, and it fits perfectly into your workflows. The integrated CAM software enables you to get started right away! Plug & Mill: Unpack, connect, start milling!

EASE OF USE

The simple commissioning and operation enable the E5 to fit perfectly into your workflows. The integrated CAM software enables you to get started right away.

Plug & Mill: Unpack, connect, start milling!

FLEXIBILITY

The machine uses no compressed air, and is therefore very easy to transport and can be set up anywhere. You can mill almost all the common materials and exploit the greatest freedom of indication.

EFFICIENCY

The open system architecture of the E5 makes your entry into the digital production of dental restorations quick and easy – it fits perfectly into your workflows. You can also benefit from minimal operating costs as the system uses no compressed air.

SERVICE? EASY!

If your machine requires servicing, the central components, e.g. the spindle and control unit, are easy to replace and you can even service the machine yourself in just a few steps.

SUSTAINABLE

The patent-pending AIRTOOL uses the energy of the spindle to keep the workpiece free of chippings. The E5 therefore operates with no compressed air and is particularly sustainable. In addition, the lightweight and service-optimized design saves transport time and resources.

QUALITY

Developed and manufactured in Germany, the E5 is made from uncompromisingly high-quality industrial components despite its low weight of only 43 kg. The result: fast machining times and the best production results.

5-axis milling machine with a powerful 800 W 60,000 rpm spindle.

Thickness 10 – 40 mm, additional holder for blocks also available.

Processes almost all materials from composites from zirconia, PMMA to CoCr sintering metals.

Operation without the use of compressed air with the innovative AIRTOOL.

Automatic changer for 16 tools and an AIRTOOL.

Simple operation with the integrated CAM software DENTALCAM featuring DIRECTMILL technology – no license fees payable.

Material, manufacturer, indication –

with the E5 you have maximum autonomy and

can mill almost all materials from composites and

zirconia to CoCr sintering metals as a disc or block.

Composites

PMMA & Wax

Zirconia

CoCr sintering metals

Greatest indication diversity with a rotating angle of ± 35° in the 5th axis and discs up to 40 mm thick.

Free Shipping On US

Return Within 30 Days

Safe & Secure Payment

Contact 24 Hours Day

Copyright © Dental Pioneers 2022.

Reviews

There are no reviews yet.